Thermoform

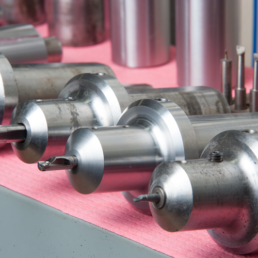

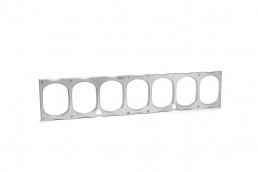

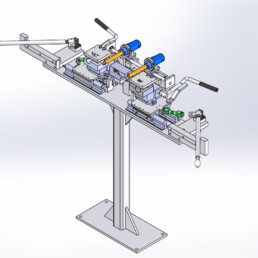

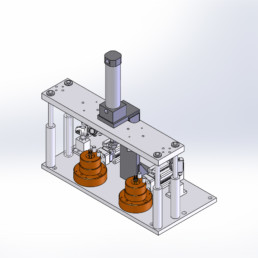

Flare specializes in thermoform tool machining and repair and has over 35 years of experience in the thermoform tooling business. Whether your project calls for a complete design of thermoform tooling, or just production from a current design, Flare’s talented staff of machinists and toolmakers can get the job done. Flare is a “one-stop-shop” for all of your machining needs. Flare has manufactured many prototype and production cavities and tooling assemblies for many top thermoforming companies.

Flare has experience cutting molds for equipment from a variety of machine manufacturers. Flare can cut a single prototyping set of tooling on up to a 40 mold set of production tooling and beyond. There is no limit to the number or quality of the molds which can be produced, sandblast finish up to polished SPI B1 type finishes.

The Person, Their Title

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras laoreet turpis at eros vestibulum, nec porttitor neque varius. Aenean eu lacus interdum felis lobortis tempus quis nec tortor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras laoreet turpis at eros vestibulum, nec porttitor neque varius. Aenean eu lacus interdum felis lobortis tempus quis nec tortor. The Person, Their Title

Another Person, What They Do

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec sit amet justo eleifend, semper nunc eu, rhoncus enim. Fusce congue hendrerit enim nec porttitor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec sit amet justo eleifend, semper nunc eu, rhoncus enim. Fusce congue hendrerit enim nec porttitor.Another Person, What They Do

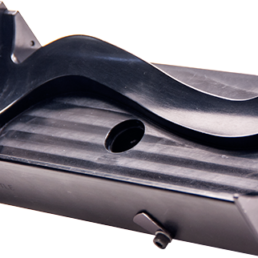

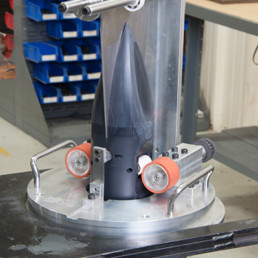

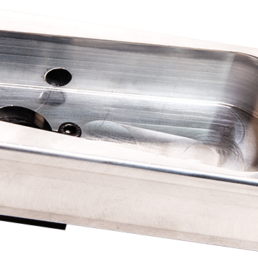

In a production environment mistakes often happen quickly and can cause costly downtime and production delays. Flare offers rapid turnaround repair services for thermoform tooling and cavity repairs. Even the most difficult or seemingly impossible damaged items can often be repaired by the expert toolmakers at Flare. The staff of machinists and welders can repair almost any damaged part with precision and speed, getting you back up in production as quick as possible. Jobs can be updated to RUSH status and can be completed in as little as a few hours depending on the complexity of the repair.

Even if the tooling is old and no engineering documents exist, Flare staff can often hand work cavities back into a usable state relying on the years of experience in the thermoform industry as a guide. The gallery below with examples of damages thermoform tooling Flare was able to repair quickly and with the utmost quality! Flare can help you reduce your costly downtime which helps you save and make more money.

In the rare case a part cannot be salvaged, Flare engineering staff will reverse engineer the part and offer a replacement cost for making a new part. This service has helped Flare save our customers thousands of dollars in costly down time due to a single damaged cavity or thermoform tooling for which no documentation or 3D model exist. Leverage the knowledge and experience of Flare today to help save money and put it back where it belongs, the bottom line.